New England Skilled Trades: Labor, Wages & Certification Gaps

June 4th, 2025

3 min read

If you're trying to staff a commercial jobsite or get a service call completed on time, you’ve likely noticed how difficult it’s become to find experienced HVAC techs and plumbers. Delays, cost increases, and workforce gaps are becoming the norm, not the exception. The skilled trades workforce is under pressure, and it’s impacting businesses across New England.

At Harold Brothers Mechanical Contractors, we manage mechanical construction and service projects every day across Massachusetts, Rhode Island, and New Hampshire. Whether we’re working on large-scale healthcare facilities or fast-turnaround service calls, we see firsthand how labor shortages, shifting wage expectations, and evolving certification requirements are reshaping the industry.

In this article, you’ll learn what’s driving the skilled trades shortage, how much HVAC, plumbing, and refrigeration professionals are making in New England, and what new certification trends you need to be aware of. We’ll also point you to trusted resources and explain what it all means for your project planning and strategy.

There Aren’t Enough Tradespeople in 2025

Across the U.S., there’s a growing gap between how many skilled tradespeople are needed and how many are actually available. According to Pride Industries, the U.S. currently faces a shortage of over 110,000 HVAC technicians. And by 2027, there may be a shortfall of more than 550,000 plumbers nationwide.

New England mirrors this national trend. Even in states like New Hampshire, which saw labor force growth in 2024, experts warn that this may not be sustainable without a new generation entering the trades.

The demand for buildings, renovations, and energy-efficient systems continues to rise, while the labor pool shrinks.

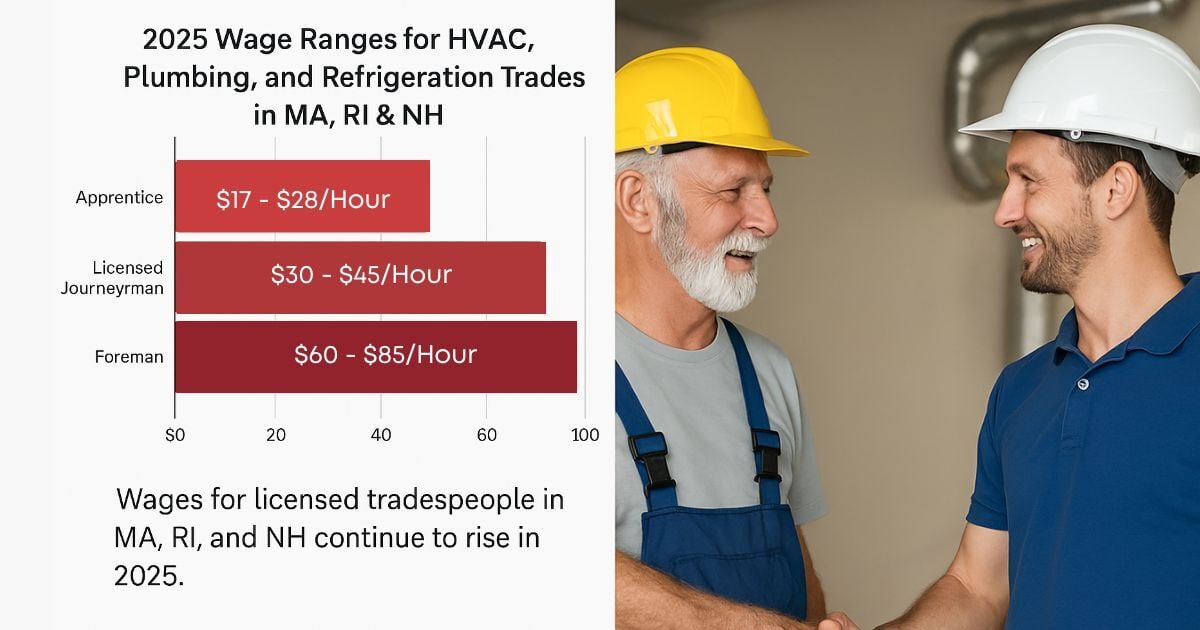

What Plumbers, HVAC Techs, and Refrigeration Technicians Are Earning in New England

If you're hiring—or planning your own skilled trades career—it’s important to understand how wages are shifting across Massachusetts, Rhode Island, and New Hampshire.

- Apprentices in plumbing, HVAC, and refrigeration roles typically earn between $17 and $33 per hour, depending on experience, training, and location. These entry-level positions often involve structured learning and on-the-job training.

- Licensed journeymen usually make between $30 and $50 per hour, with higher wages for those working on large-scale commercial or industrial systems. Specialized certifications can also increase earning potential.

- Foremen and lead technicians, who manage crews and oversee daily jobsite operations, can earn $50 to $80 per hour.

Experienced workers may earn even more when factoring in overtime or rate work.

These figures underscore the importance of budgeting appropriately for skilled labor. For insights into managing these costs, explore our article on the costs of commercial HVAC Maintenance in Massachusetts.

For project owners planning state or municipal construction, the Massachusetts Prequalification Guidelines provide helpful insight on wage rules and contractor requirements.

Retirement Is Shrinking the Workforce Faster Than It’s Growing

Another key challenge? The average age of skilled tradespeople continues to climb. Many professionals with decades of hands-on experience are now retiring, and there aren’t enough new workers entering the pipeline to replace them.

This retirement wave is especially problematic for HVAC and plumbing, where much of the job knowledge is passed down through field experience. Without strong mentorship, hands-on training, and career awareness starting at the high school level, that experience is lost, and projects suffer.

Certification Requirements Are Quickly Evolving

Staying certified isn’t just a box to check—it’s critical to staying compliant with evolving federal and state regulations. Over the past year, several big changes have come down the pipeline:

1. New Energy Efficiency Standards (SEER2 & HSPF2)

The U.S. Department of Energy now requires HVAC equipment to meet stricter energy standards. New SEER2 and HSPF2 ratings mean technicians must understand how to install and troubleshoot more efficient systems, and that older certifications may no longer meet updated standards.

2. Refrigerant Regulations Are Shifting

As part of its push toward environmental responsibility, the EPA is phasing out high-GWP (global warming potential) refrigerants and requiring the use of low-GWP alternatives. This shift requires additional training, tools, and safety precautions.

Techs who aren’t up to date risk falling behind or worse, putting systems at risk of failure or noncompliance.

To support ongoing education, Harold Brothers offers resources through the Harold Brothers Training Institute, providing safety and technical training for our team and the broader community.

What It Means for Owners, Managers, and General Contractors

All of this, labor shortages, rising wages, and evolving standards, adds complexity for anyone planning a commercial plumbing or HVAC project in New England.

- Fewer tradespeople = longer lead times

- Rising wages = higher labor costs

- Certification changes = increased training requirements

- Prevailing wage = budgeting considerations for public/commercial projects

That’s why it’s more important than ever to work with mechanical contractors who invest in training, stay ahead of regulatory changes, and have the workforce capacity to deliver on time and on budget.

What This Means for Your Next HVAC or Plumbing Project

At the end of the day, we’ve all encountered the frustrations of delayed jobs, spiraling labor costs, and thin project pipelines due to the skilled trades shortage. This is especially true if you’re managing commercial projects in New England, where retirement waves and new certification requirements make hiring even more complex.

Now that you’ve learned from Harold Brothers what’s driving these challenges—and what wage and certification shifts to watch for—it’s time for you to act strategically.

Your next step: Start your hiring and planning process earlier, and align with mechanical contractors who invest in training and regulatory compliance. The sooner you adjust, the smoother your timelines and budgets will run.

At Harold Brothers Mechanical Contractors, we’re not just aware of these trends—we’re actively addressing them every day across Massachusetts, Rhode Island, and New Hampshire. Whether it’s labor strategy, project forecasting, or regulatory guidance, we’re here to help you move forward in your next project with confidence.

John Flaherty is the Senior Director of Business Development at Harold Brothers Mechanical, where he plays a key role in fostering client relationships and driving strategic growth. With nearly two decades of experience holding a real estate license, John brings a deep understanding of business development and market dynamics to his role. Before joining Harold Brothers, John dedicated 15 years to education administration at Boston College High School, where he helped shape institutional advancement efforts. A proud alumnus of BC High, he continues to serve on the school's Alumni Advisory Council, strengthening connections within the community. As a contributing author for Harold Brothers Mechanical, John leverages his diverse professional background to provide insightful articles on industry trends, business strategies, and company developments.

Topics: