If you’ve ever received a quote for commercial HVAC or plumbing work and noticed that prices changed a few weeks later, you're not alone—and you're not imagining things. The mechanical contracting industry is facing some of the most volatile pricing conditions in decades.

At Harold Brothers, we believe in transparency. That means helping you understand not just what something costs, but why it costs what it does—and why that number might change from one month to the next.

This article breaks down the major causes of price volatility in our industry, so you can better plan for your mechanical projects, communicate with stakeholders, and make confident budgeting decisions.

Why Commercial HVAC and Plumbing Prices Fluctuate

The cost of HVAC and plumbing work can shift quickly due to factors outside any contractor’s control.

Here are the key reasons you might see pricing change over time:

1. Material Costs, Like Copper and Steel, Impact Your HVAC and Plumbing Quote

Key materials like copper, stainless steel, aluminum, and galvanized steel are at the core of almost every HVAC or plumbing system. These materials are global commodities, and their prices are affected by:

For example, copper prices surged over $5 per pound in 2025, driven by tariff announcements and tight global supply. Steel prices have also climbed as much as 30–70% over short periods, making a direct impact on the cost of piping, ductwork, and structural supports.

2. HVAC and Plumbing Equipment Delays: What’s Causing Long Lead Times?

Certain components critical to HVAC and plumbing systems are still experiencing delays and backlogs. Some of the most commonly affected parts include:

- Air handling units (AHUs)

- Packaged rooftop units (RTUs)

- Control boards and building management systems

- Condensing units and compressors

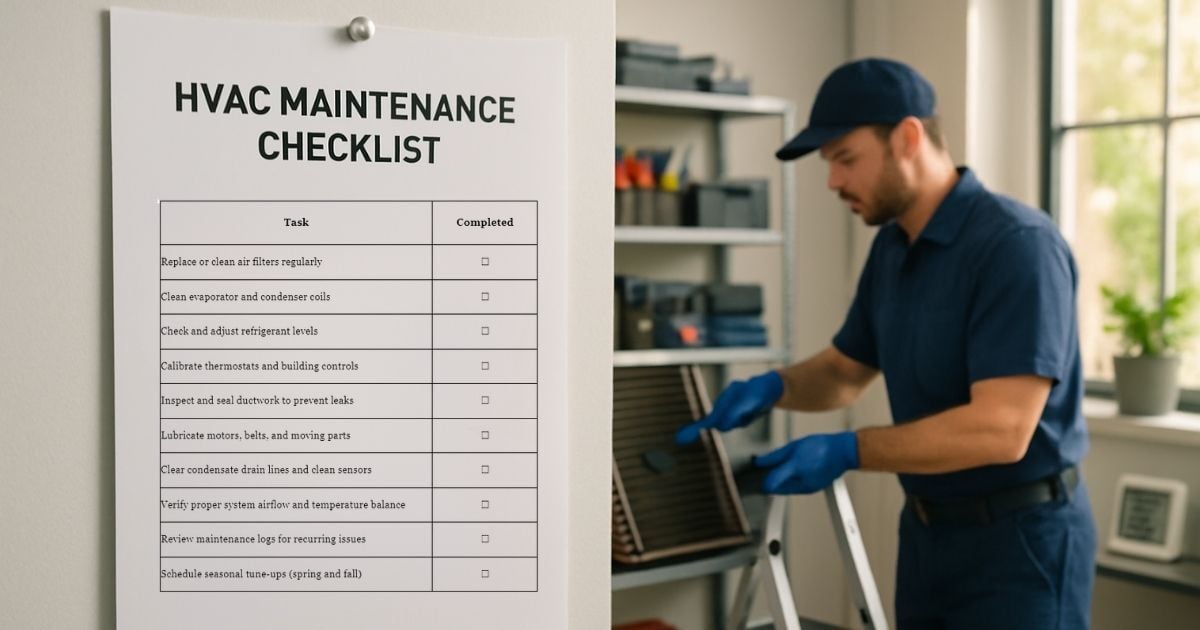

As of early 2025, many of these parts have lead times stretching 18 to 22 weeks, depending on size and accessories (Worthing Air). Manufacturers are still catching up from pandemic-era slowdowns and material shortages, and lead times are expected to stay long throughout the year. To reduce downtime, many businesses are taking a proactive approach by stocking essential HVAC parts in advance.

3. How Freight and Fuel Costs Drive Up HVAC and Plumbing Project Prices

Shipping, fuel, and logistics play a huge role in mechanical contracting, especially for large equipment and multi-site projects. Price volatility in this area is driven by:

If a rooftop unit has to be shipped across the country or craned onto a building, freight and rigging costs can significantly increase the overall price, even if the equipment cost remains stable.

4. Why Skilled Labor Shortages Are Increasing Mechanical Project Costs

Skilled mechanical labor in New England remains in high demand. Licensed plumbers, pipefitters, and HVAC technicians are being pulled into competing projects, which results in:

- Higher hourly wages and overtime

- Scheduling delays during peak season

- Pressure on project timelines

The shortage of qualified HVAC technicians continues to strain the market, especially as retirement rates climb.

5. How Changing Codes and Regulations Affect HVAC and Plumbing Pricing

Shifts in energy codes, refrigerant regulations, and local ordinances can affect both project scope and equipment selection. For example:

- Many refrigerants are being phased out due to environmental concerns

- Energy codes may require more efficient equipment with longer lead times

- Plumbing codes are evolving, sometimes requiring alternate materials

These changes can occur quickly and without much notice, impacting cost and availability almost overnight.

How to Plan for Cost Fluctuations in Commercial HVAC and Plumbing Projects

While price fluctuations are often out of your control, there are smart ways to plan ahead. Start by engaging your mechanical contractor early in the budgeting process so they can help identify potential risks and lock in current pricing where possible.

Build contingency into your estimates to account for unexpected cost changes. Stay flexible with your equipment selections, as alternative products may be more readily available or cost-effective.

Finally, act promptly when pricing and lead times align—delays can lead to both higher costs and extended project timelines.

How to Stay Ahead of Rising HVAC and Plumbing Costs

Understanding why HVAC and plumbing prices change so frequently can help you plan better, communicate with stakeholders, and avoid surprises. This article has unpacked the key reasons behind those shifts—from commodity pricing and equipment delays to fuel costs and labor shortages—so you can make more informed budgeting decisions.

If you’ve already received a quote, you’re working within a limited window. Pricing conditions are shifting constantly, and if the quote expires before you sign, your project could be subject to updated costs and extended timelines. That number you’re looking at today reflects a moment in time, and that moment is temporary.

Now that you know what drives these fluctuations, your best move is to act before conditions shift again. Whether you’re ready to move forward or need to talk through specifics, we’re here to help you protect your budget and stay on schedule. Explore our mechanical contracting services to see how we manage cost risks and keep projects on track.

At Harold Brothers, we don’t just install mechanical systems—we guide you through a complex and fast-changing industry. Let’s talk early, plan smart, and build with certainty—because transparency isn’t just a value for us, it’s how we do business