What to Think About Before Renovating Your Warehouse

October 31st, 2025

4 min read

Before renovating your warehouse, you need to understand how your building’s existing mechanical systems will support or limit your plans. Taking the time to evaluate HVAC, plumbing, and layout needs early can prevent major delays, code issues, and unexpected costs.

We recently worked with a warehouse owner in southern Massachusetts who was adding office space and upgrading their storage layout. Their mechanical systems hadn’t been touched in over 20 years. After a quick review, we found the HVAC units were undersized for the new square footage, and the plumbing lines needed to be relocated to accommodate the new restrooms. Planning these updates ahead of time saved the project from weeks of rework and thousands in unplanned costs.

In this article, we’ll explain what to evaluate before a warehouse renovation, which systems you should inspect first, and how early planning can help your project run on time and on budget.

Why Should You Evaluate Your Building Systems Before Renovation?

When most people plan renovations, they focus on layout and finishes. But your building’s mechanical systems are its backbone. They determine comfort, functionality, and long-term operating costs.

Ignoring these systems can lead to expensive surprises once construction begins, such as outdated ductwork, insufficient water pressure, or equipment that no longer meets Massachusetts code requirements. Ignoring hidden system issues; like pipe leaks, outdated fixtures or failing drains, can trigger the kinds of problems outlined in our article on Common Commercial Plumbing Repairs Every Facility Manager Should Know

.

A detailed pre-renovation assessment provides:

- A clear understanding of your current infrastructure

- Accurate project costs and timelines

- Fewer change orders and schedule delays

- Opportunities to improve efficiency before ceilings and walls are sealed

In short, early system planning keeps your renovation efficient, compliant, and future-ready.

What Building Systems Should You Inspect First?

Start by evaluating the three systems that have the greatest impact on performance: HVAC, plumbing, and electrical.

HVAC

Determine whether your system can handle changes in square footage, ceiling height, or building use. If you’re converting warehouse space into offices, your existing units may not meet new ventilation or zoning requirements. You might need to resize ductwork, add return vents, or upgrade to an energy-efficient variable refrigerant flow (VRF) system.

It’s also worth reviewing long-term utility and maintenance expectations, see our breakdown of Annual HVAC Operating Costs for New England Commercial Buildings to understand what older or undersized units steal from your budget.

Plumbing

Warehouse plumbing is often minimal, but renovations can complicate things quickly. Adding restrooms, breakrooms, or washdown areas requires re-routing water and drain lines. In older facilities, this can reveal corroded pipes or outdated materials that fail modern codes. Checking these systems early helps you avoid costly mid-project corrections.

Because your facility is being repurposed, you’ll want to avoid the root causes of costly plumbing failures, we’ve outlined them in Avoid These 7 Commercial Plumbing Issues with Regular Maintenance.

Electrical

Adding lighting, automation, or new equipment means verifying that your power supply and electrical panels can handle the load. Many older warehouses lack dedicated circuits, surge protection, or capacity for modern systems.

Inspecting these systems early allows you to plan proactive upgrades instead of reactive fixes.

How Do Building Codes and Permits Affect Your Renovation?

Massachusetts building and energy codes change frequently. What passed inspection a decade ago may no longer meet today’s standards for ventilation, accessibility, or energy use. Before finalizing your design, review local requirements that apply to your project.

For example:

- HVAC and lighting systems must comply with the Massachusetts Stretch Energy Code for energy efficiency.

- Plumbing fixtures must meet WaterSense or other low-flow standards.

- New office or restroom spaces must follow ADA accessibility guidelines.

- Fire protection systems must include adequate sprinkler or suppression coverage based on the new layout.

Working with your mechanical contractor during the design phase ensures these requirements are addressed early, saving time, money, and frustration during inspections.

How Can You Improve Energy Efficiency During Renovation?

A renovation is the perfect opportunity to reduce long-term utility costs. Older HVAC units, uninsulated pipes, and outdated lighting can quietly waste energy and inflate operating expenses.

Consider these upgrades for faster payback:

- Install high-efficiency HVAC systems with smart controls or variable-speed fans.

- Add insulation and air sealing around dock doors and ceilings to reduce heat loss.

- Replace older plumbing fixtures with low-flow or sensor-activated models.

- Integrate a Building Management System (BMS) to automate heating, cooling, and lighting schedules.

Programs like Mass Save offer incentives to offset upgrade costs. Making these improvements now means lower bills and better performance for years to come. Integrating a BMS is one of the smartest moves you can make, check out our article on how a building management system can save you money for how this applies to HVAC, plumbing and lighting together.

When Should You Bring in a Mechanical Contractor?

The best time to involve a mechanical contractor is before your architectural plans are finalized. Early collaboration ensures your design aligns with the building’s system capacities and prevents oversights like:

- Ductwork interfering with new racking or mezzanines

- Restrooms placed too far from existing water lines

- Electrical loads exceeding panel capacity

By bringing a mechanical expert into the design phase, you ensure every upgrade is practical, compliant, and cost-effective from the start.

Why Is Preventive Maintenance Part of a Good Renovation Plan?

Renovations often uncover long-hidden issues such as worn belts, rusted pipes, or clogged filters. Including maintenance in your renovation plan helps your systems start strong once construction ends.

Before your renovation wraps up, make sure you:

- Replace HVAC filters and clean coils

- Test and flush water lines

- Calibrate thermostats and sensors

- Schedule your first post-renovation maintenance check

These simple steps ensure your systems operate efficiently from day one and extend the life of your investment.

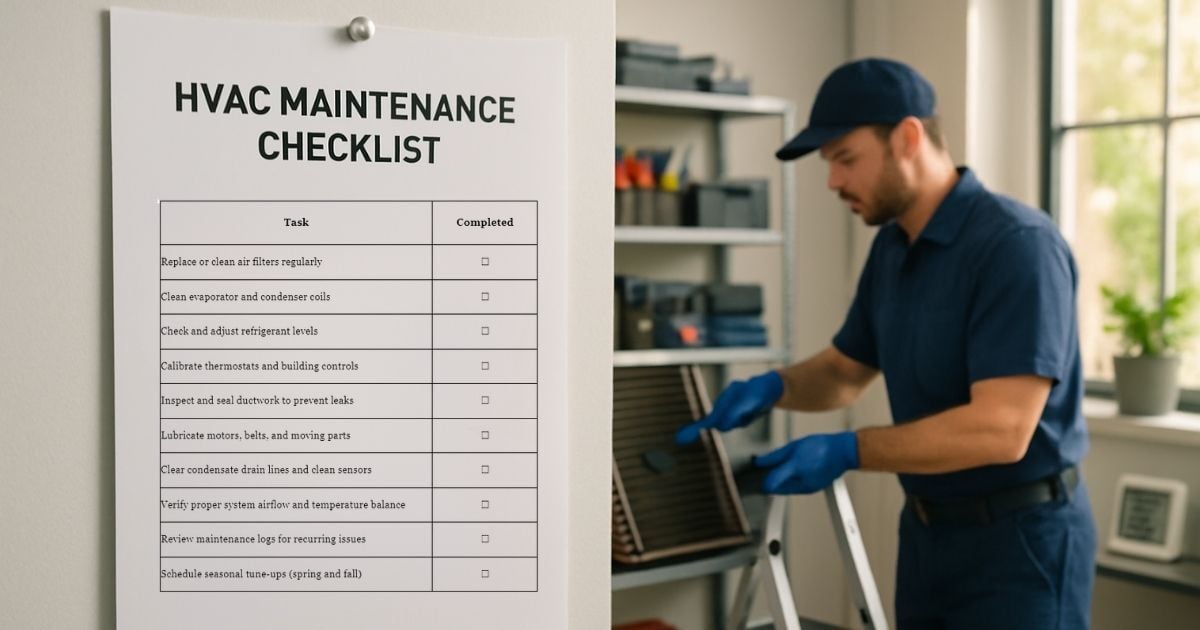

Warehouse Renovation Planning Checklist

|

Task |

Completed |

|

Inspect HVAC capacity and duct layout |

☐ |

|

Review plumbing layout and fixture needs |

☐ |

|

Evaluate electrical loads and panel capacity |

☐ |

|

Confirm code and permit requirements |

☐ |

|

Plan for energy-efficiency upgrades |

☐ |

|

Schedule an early consultation with mechanical contractor |

☐ |

|

Review insulation and building envelope needs |

☐ |

|

Budget for preventative maintenance |

☐ |

|

Verify fire protection and sprinkler coverage |

☐ |

|

Establish a project timeline with all trades |

☐ |

What’s the Real Takeaway on Warehouse Renovations?

Renovating your warehouse is more than just a facelift. It’s your chance to build efficiency, comfort, and reliability into your facility for years to come.

By reviewing your HVAC, plumbing, and electrical systems early, you avoid costly surprises and gain the opportunity to improve performance across the board.

If you’re ready to explore smart, cost-saving improvements for your facility, read our next article: Best Commercial Plumbing Upgrades for Warehouses to see how simple plumbing improvements can make your renovation even more efficient.

At Harold Brothers Mechanical Contractors, we’ve helped warehouses and industrial facilities across Massachusetts plan smarter renovations, improve building performance, and avoid unexpected costs. Whether you’re upgrading a single system or redesigning your entire space, our team can help you get it right from the start.

John Flaherty is the Senior Director of Business Development at Harold Brothers Mechanical, where he plays a key role in fostering client relationships and driving strategic growth. With nearly two decades of experience holding a real estate license, John brings a deep understanding of business development and market dynamics to his role. Before joining Harold Brothers, John dedicated 15 years to education administration at Boston College High School, where he helped shape institutional advancement efforts. A proud alumnus of BC High, he continues to serve on the school's Alumni Advisory Council, strengthening connections within the community. As a contributing author for Harold Brothers Mechanical, John leverages his diverse professional background to provide insightful articles on industry trends, business strategies, and company developments.