How Often Should HVAC Preventive Maintenance Be Done in Massachusetts?

December 1st, 2025

4 min read

By Lisa Flynn

If you manage a commercial building in Massachusetts, your HVAC system faces more pressure than systems in many other areas. Winter brings long stretches of freezing temperatures. Summer introduces heavy humidity and warm air. Along the coastline, salty winds can wear down equipment even faster. With these conditions, regular HVAC preventative maintenance is not only recommended but essential.

So how often should preventative HVAC maintenance be done?

Most buildings need two visits each year. In Massachusetts, many systems benefit from three or even four visits because of the climate, coastal exposure, and the age of many commercial buildings across the state.

This guide explains how often maintenance should happen, what each visit includes, and how local conditions influence your ideal schedule.

Why Preventative Maintenance Matters

Preventative maintenance is one of the most valuable investments a building owner or facility manager can make. When equipment is cleaned, inspected, and adjusted regularly, it runs more efficiently, lasts longer, and avoids many mid-season failures.

Skipping even one season of maintenance increases the risk of rising utility bills, airflow issues, unexpected shutdowns, and premature equipment failure. Coastal buildings face the added challenge of corrosion.

With consistent maintenance, Massachusetts buildings often see lower energy use, steadier indoor comfort, better air quality, and a longer equipment lifespan. Regular maintenance also helps protect warranties and maintain compliance with safety and manufacturer standards.

How Often Should HVAC Systems Be Serviced?

g system for the warmer months. A fall visit prepares the heating system for the colder months. These two appointments create a solid maintenance foundation.

Massachusetts buildings often need more frequent service because of our unique climate. Coastal buildings, older systems, and facilities with continuous or heavy usage may need three or four visits each year. Locations near the ocean often benefit from additional summer or early winter inspections to check for corrosion, salt buildup, and humidity-related issues.

Buildings that operate around the clock, such as data centers, healthcare facilities, or labs, also require more frequent checks.

How Massachusetts Weather Affects HVAC Maintenance Frequency

Weather conditions in Massachusetts play a major role in how often systems should be serviced.

Winter places intense strain on heating components. Systems often run for long hours and have very little downtime. Summer brings humidity that puts extra pressure on cooling components, especially on buildings near the coast. Humid, salty air speeds up wear on coils, motors, and electrical parts.

Spring and fall can expose issues developed during the previous season. As systems switch between heating and cooling, problems like refrigerant leaks, worn electrical connections, and airflow imbalances often become noticeable. A preventative maintenance visit right before these seasonal shifts offers the best protection.

What Happens During a Preventative Maintenance Visit?

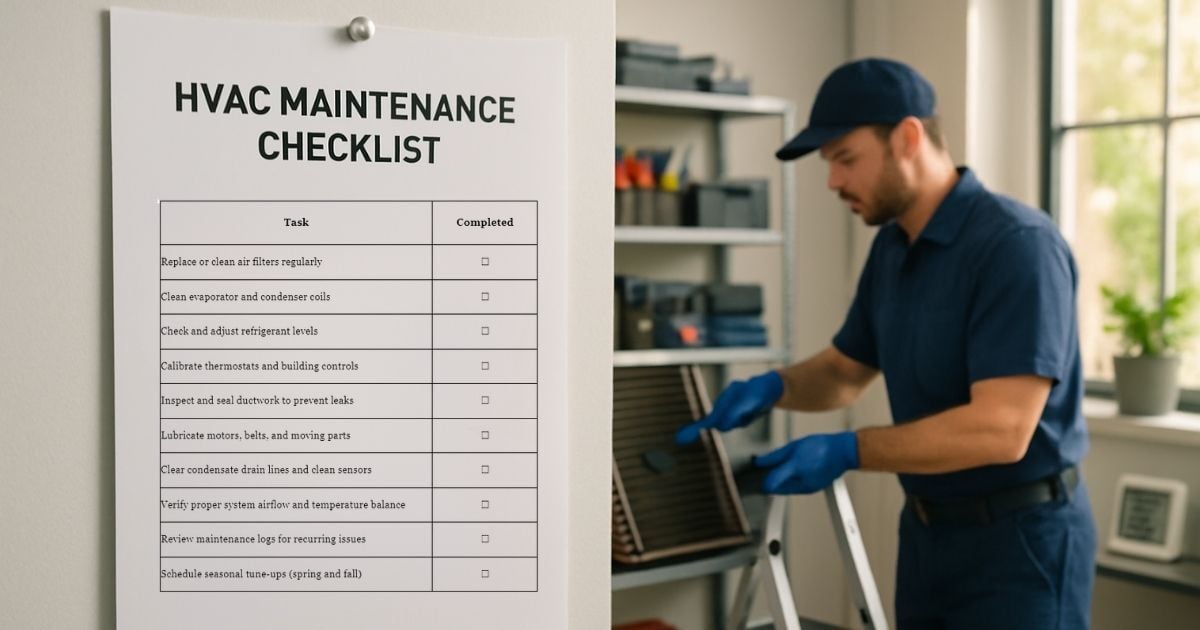

Each maintenance visit focuses on cleaning, inspection, performance testing, and safety checks. A technician will examine filters, coils, motors, belts, fans, electrical connections, controls, and ductwork. They will clear drains, test refrigerant levels, clean coils, and verify proper heating or cooling performance.

Coastal buildings often receive additional attention. Salt exposure can cause quicker deterioration of coils and metal surfaces, so technicians may use corrosion protection, salt-neutralizing cleaners, or a more detailed inspection of outdoor units. These steps help preserve equipment that faces more aggressive environmental conditions.

What Seasonal Maintenance Should Include

A spring maintenance visit prepares your building for warm weather. The technician cleans the condenser coils, checks refrigerant levels, tests the thermostat, clears drains, and ensures the system is ready for frequent summer use.

A fall visit prepares your heating system for cold weather. The technician inspects the burners and ignition systems, checks heat exchangers, tests safety controls, replaces filters, and confirms that your system is safe and ready for winter.

Some buildings benefit from additional visits during early summer or before winter. These appointments are especially helpful for coastal locations or older systems. A short pre-winter inspection can help identify corrosion or electrical damage that could lead to problems once temperatures drop.

When Quarterly Maintenance Makes Sense

Some buildings have stricter requirements or heavier usage that makes quarterly preventative maintenance the smarter choice. This includes hospitals, labs, biotech buildings, food service operations, manufacturing facilities, data centers, and industrial plants. These environments rely on consistent temperature control, have sensitive equipment, or operate continuously.

Buildings close to the ocean also benefit from quarterly visits because of the faster rate of corrosion. Even small amounts of salt exposure can significantly reduce the lifespan of outdoor HVAC equipment.

Signs You May Need More Frequent Maintenance

You may want to increase your maintenance frequency if your building experiences higher energy bills, inconsistent temperatures, unusual noises or odors, frequent repairs, rust on outdoor units, humidity issues, or system age above ten years.

If more than one of these signs appears, a higher frequency plan generally pays for itself through reduced downtime and lower repair costs.

Does Preventative Maintenance Save Money?

Yes. Regular maintenance often reduces energy waste by ten to twenty-five percent. For many commercial buildings, this results in meaningful annual savings.

Preventative maintenance also reduces the likelihood of costly emergency repairs during peak seasons. In many cases, one avoided emergency visit can cover the cost of the entire maintenance plan.

What Does This Mean For You?

Preventive maintenance is one of the most effective ways to protect your HVAC system in a state like Massachusetts, where winter, summer, and coastal conditions all place extra demand on your equipment. With the right maintenance schedule in place, you can reduce downtime, avoid surprise repairs, and keep your building running smoothly.

Now that you understand how often preventative maintenance should be done, and how local factors like humidity, salt exposure, and older buildings influence that timeline, you are better prepared to choose a plan that truly fits your property. Regular care not only prevents problems. It also extends equipment life, improves comfort, and helps you control long-term operating costs.

If you would like help determining the right maintenance schedule for your building, your next best step is to request more information from the Harold Brothers team. This will give you a clear understanding of what your building needs, what is included in a full preventative maintenance program, and what frequency makes the most sense for your equipment.

For more than seventeen years, Harold Brothers has helped commercial buildings across Massachusetts stay efficient, reliable, and comfortable through high-quality HVAC and plumbing preventative maintenance. If you want a plan tailored to your building’s age, location, and mechanical systems, we are here to guide you toward the best long-term solution.

FAQ

How Long Does a Preventative Maintenance Visit Take?

Most visits take one to four hours depending on system size and complexity.

What is Included With a Preventive Maintenance Plan?

A visit typically includes filter changes, coil cleaning, inspections, testing, and digital documentation.

How often should Preventative Maintenance Visits Occur?

Twice per year for most buildings. Coastal or high-use facilities benefit from quarterly visits.

With over 39 years of experience in the HVAC industry, Lisa Flynn brings a wealth of knowledge, reliability, and proven leadership to every project. She has a demonstrated track record of managing and mentoring HVAC service technicians while collaborating closely with project managers to ensure the successful execution of construction projects. Lisa's expertise spans a broad range of critical functions, including dispatching service calls, budget preparation and management, billing and collections, and project quoting. She has cultivated strong client and customer relationships through her attention to detail and commitment to delivering exceptional results. From marketing and advertising initiatives to equipment procurement, tracking, and project close-outs, Lisa consistently drives efficiency and excellence at every stage. Her hands-on approach and dedication to exceeding expectations make her a trusted partner for clients and colleagues alike.

Topics: