If your HVAC system isn’t regularly maintained, you’re likely dealing with rising energy bills, surprise breakdowns, and compliance headaches.

For facilities like schools, hospitals, and office buildings, these issues can lead to uncomfortable occupants, emergency repair costs, and even operational downtime.

At Harold Brothers Mechanical Contractors, we’ve managed thousands of HVAC systems through preventative maintenance (PM) contracts, helping facility managers like you avoid those exact problems. With decades of field experience, our team understands how to tailor maintenance plans based on your building’s size, usage, and equipment type, ensuring maximum reliability and compliance.

In this article, you’ll learn exactly how our PM contracts are structured, from the first site visit to seasonal changeovers, so you can decide what maintenance plan is right for your facility.

How Do You Start a PM Contract?

Every PM contract begins with a detailed site visit and equipment review. Before you sign on the dotted line, our service manager or lead technician will meet with you to review your system list, site access, and priorities.

During this setup phase, our technician:

- Log all HVAC equipment by make, model, serial number, and location.

- Review performance data and any previous maintenance records.

- Identify immediate repair or code issues.

- Enter your system into our scheduling software for automatic visit reminders.

This process ensures every technician visit is efficient and consistent. You’ll likely see the same tech or service team each time, so they become familiar with your system’s layout and performance.

What is The Maintenance Schedule?

Not every building requires the same service frequency. At Harold Brothers, we customize PM schedules based on system size, building use, and mechanical complexity.

Here’s how it generally breaks down:

- Monthly Service: For large facilities like hospitals, labs, and data centers where HVAC reliability is critical.

- Quarterly Service: For commercial systems such as schools or mixed-use buildings.

- Bi-Annual Service: For smaller facilities, offices, warehouses, or properties with seasonal usage.

Each schedule includes seasonal inspections that align with heating and cooling changeovers. For example, your spring visit prepares your system for the cooling season, while the fall visit gets you ready for winter.

What Happens During Each Maintenance Visit

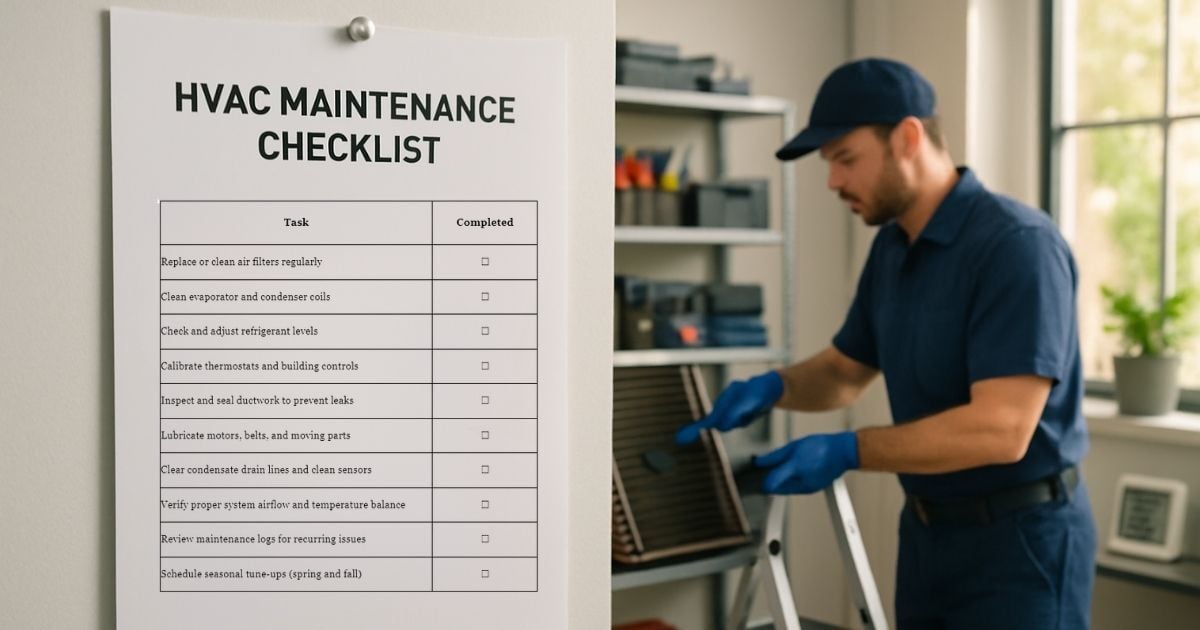

When your Harold Brothers technician arrives, the visit is structured to check, clean, and test your system for safe and efficient performance. Each step follows a consistent checklist to ensure nothing is missed.

A Typical PM Visit Includes:

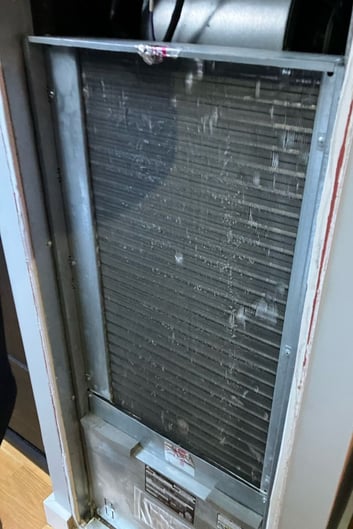

- Checking and replacing air filters, belts, and bearings. Check out why changing your air filters is so important.

- Cleaning coils, condensate drains, and strainers.

- Testing thermostats, controls, and sensors for proper operation.

- Inspecting electrical connections and safety components.

- Measuring refrigerant levels and checking for leaks.

- Confirming startup and shutdown sequences.

- Recording system pressures, temperatures, and operating data.

- Expecting the heat exchanger

At the end of each visit, you receive an XOI service report that summarizes all findings and recommendations. Reports often include photos and notes from your technician so you can easily track performance over time.

Seasonal Changeovers and Specialty Inspections

HVAC systems behave differently depending on the season, which is why PM contracts are scheduled to support those changes.

Spring and Summer Visits

Your technician focuses on cooling performance. They’ll clean condenser coils, inspect refrigerant lines, clear drain lines, and verify that fans, blowers, and thermostats are operating efficiently.

Fall and Winter Visits

These visits prepare your system for heating. The team checks burners, gas pressures, heat exchangers, safety controls, and combustion efficiency.

Some clients also choose to add specialized inspections, such as checking to make sure the HVAC is working with the building management system, and seasonal startup and shutdown services for boilers and chillers.

Communication and Reporting Throughout the Year

Strong communication is a big part of what makes Harold Brothers PM contracts stand out. After every visit, you receive a detailed report that outlines completed work, system condition, and any issues that need follow-up.

You’ll also have a designated contact in the Service Department who handles scheduling, approvals, and future planning. This helps you stay organized, budget for upcoming repairs, and avoid emergency breakdowns.

Why Consistent Maintenance Matters

%20-%202025-12-12T073610.325.jpg?width=345&height=460&name=Untitled%20(768%20x%201024%20px)%20-%202025-12-12T073610.325.jpg) Preventative Maintenance isn’t just a checklist. Our HVAC Maintenance article details some of the reason's preventative maintenance is key in preventing problems. It’s an investment in long-term performance. When your equipment is maintained consistently, you get measurable results:

Preventative Maintenance isn’t just a checklist. Our HVAC Maintenance article details some of the reason's preventative maintenance is key in preventing problems. It’s an investment in long-term performance. When your equipment is maintained consistently, you get measurable results:

- Fewer system failures and emergency calls.

- Lower monthly energy costs.

- Longer equipment lifespan.

- Easier capital planning for future upgrades.

Delaying or skipping visits often leads to costly repairs that could have been avoided. Regular PM ensures your building runs at peak efficiency all year.

To give you a sense of how a typical Harold Brothers PM contract flows, here’s an example of what a quarterly plan might look like:

A Year at a Glance: Your PM Timeline

|

Month |

Visit Focus |

Key Tasks |

|

January–March |

Winter Check |

Inspect heating system, replace filters, tighten belts, test safety controls. |

|

April–June |

Spring Changeover |

Clean coils, check refrigerant levels, prepare for cooling season. Switch over cooling tower or chiller from heating to cooling |

|

July–September |

Summer Operation |

Inspect condenser performance, drains, electrical components, and airflow. |

|

October–December |

Fall Changeover |

Prepare for heating, inspect burners, heat exchangers, and update system logs. Winterize cooling tower or chiller to switch from cooling to heat. |

Depending on your system type, frequency, and site conditions, your plan may include additional monthly visits, or your system might only require Spring and Fall visits.

Ready to Plan Your HVAC Maintenance Year?

At Harold Brothers, every PM visit is backed by 17+ years of mechanical expertise and a focus on proactive service. Our licensed and factory-certified technicians don’t just look for problems; they help you prevent them.

From rooftop units and boilers to VRF systems and building automation controls, we maintain it all with precision and care. Each visit keeps your equipment compliant with Massachusetts energy and safety codes and extends its useful life.

If you’re ready to take the guesswork out of HVAC maintenance, Harold Brothers can help. Visit our Preventative Maintenance Request Page.

With over 39 years of experience in the HVAC industry, Lisa Flynn brings a wealth of knowledge, reliability, and proven leadership to every project. She has a demonstrated track record of managing and mentoring HVAC service technicians while collaborating closely with project managers to ensure the successful execution of construction projects. Lisa's expertise spans a broad range of critical functions, including dispatching service calls, budget preparation and management, billing and collections, and project quoting. She has cultivated strong client and customer relationships through her attention to detail and commitment to delivering exceptional results. From marketing and advertising initiatives to equipment procurement, tracking, and project close-outs, Lisa consistently drives efficiency and excellence at every stage. Her hands-on approach and dedication to exceeding expectations make her a trusted partner for clients and colleagues alike.

Topics: